EDM Machining

EDM machining plays a crucial role in OKU’s manufacturing process, particularly for precision engineering and components demanding the highest accuracy. This technique enables us to achieve tight tolerances, outstanding surface finishes, and intricate shapes. It perfectly complements OKU’s broad range of machining services, allowing us to deliver highly precise parts and assemblies tailored to the needs of diverse industries.

What is EDM Machining?

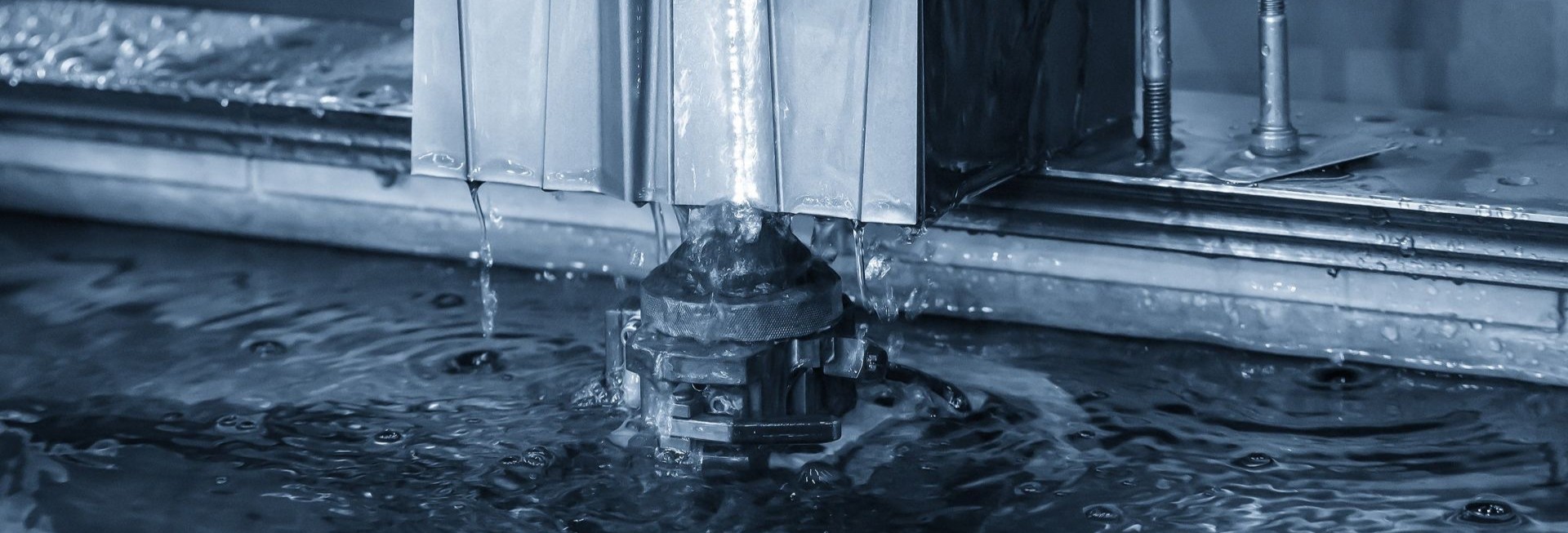

EDM (Electrical Discharge Machining), also called spark machining, is a process where material is removed from a workpiece using electrical discharges. An electric current passes from an electrode or a thin wire to the workpiece through a dielectric fluid. Each discharge produces a spark that erodes microscopic particles from the surface, which are then flushed away by the fluid.

EDM works on all electrically conductive materials, from hardened steels to softer metals. It is also ideal for brittle materials since the process doesn’t apply mechanical force that could cause stress or cracking.

The origins of EDM date back to the 1700s, when Joseph Priestley observed how electric sparks affected metal. The technique itself took shape during the Second World War, when a Soviet husband-and-wife research team, the Lazarenkos, developed the first EDM machines to tackle hard-to-machine materials.

Today, EDM machining is a vital part of modern manufacturing, enabling the production of increasingly complex and precise components with extremely tight tolerances. At OKU, we achieve accuracy down to ±0.001 mm with EDM, as well as the ability to create shapes and work with materials that traditional cutting methods simply cannot manage.

Types of EDM Machining

There are three main EDM techniques: wire cutting, sinker EDM, and EDM drilling. Each one has its own strengths and applications:

Wire Cutting – precision without mechanical stress

Wire EDM uses a thin metal wire, such as brass or zinc-coated copper, to cut through the material. It’s a highly accurate method, ideal for intricate 2D profiles and detailed cuts. Because there’s no mechanical contact, it’s perfect for hard, conductive materials where distortion must be avoided.

Sinker EDM – complex 3D shapes with accuracy

Sinker EDM uses a shaped electrode that is lowered into the workpiece while submerged in dielectric fluid. The resulting shape matches the electrode, allowing us to create deep cavities and complex 3D forms with precision. It’s an excellent solution for parts that are difficult or impossible to machine by other means.

EDM Drilling – small, precise holes in demanding materials

EDM drilling enables the creation of small, deep, and accurate holes in hard metals and other challenging materials. It’s often used to make start holes for wire cutting. Thanks to very fine electrodes, EDM drilling can produce hole dimensions that would be impossible using traditional drilling techniques.

Why Choose EDM Machining?

EDM machining seamlessly combines exceptional precision, the capability to create intricate three-dimensional shapes, and the skill to work with challenging materials. It stands as the preferred solution when conventional machining methods reach their limits. OKU’s expertise in EDM delivers solutions that prioritise quality, accuracy and functionality for our clients.

OKU (Okun Koneistuspalvelu Oy) is a company specialising in fine mechanics and precision machining. The precision parts manufactured by OKU are used in various industries where extreme accuracy and attention to detail are essential. Founded in 1978, the family-owned company has production facilities located in Outokumpu, Finland. With nearly 60 machining machines across two factories, the company uses modern automated technology. OKU employs approximately 40 people. For more information, visit www.oku.fi.